The "main artery" of the belt conveyor system”: Material Mechanics and Performance Balance in Hyundai Conveyor Belt Selection

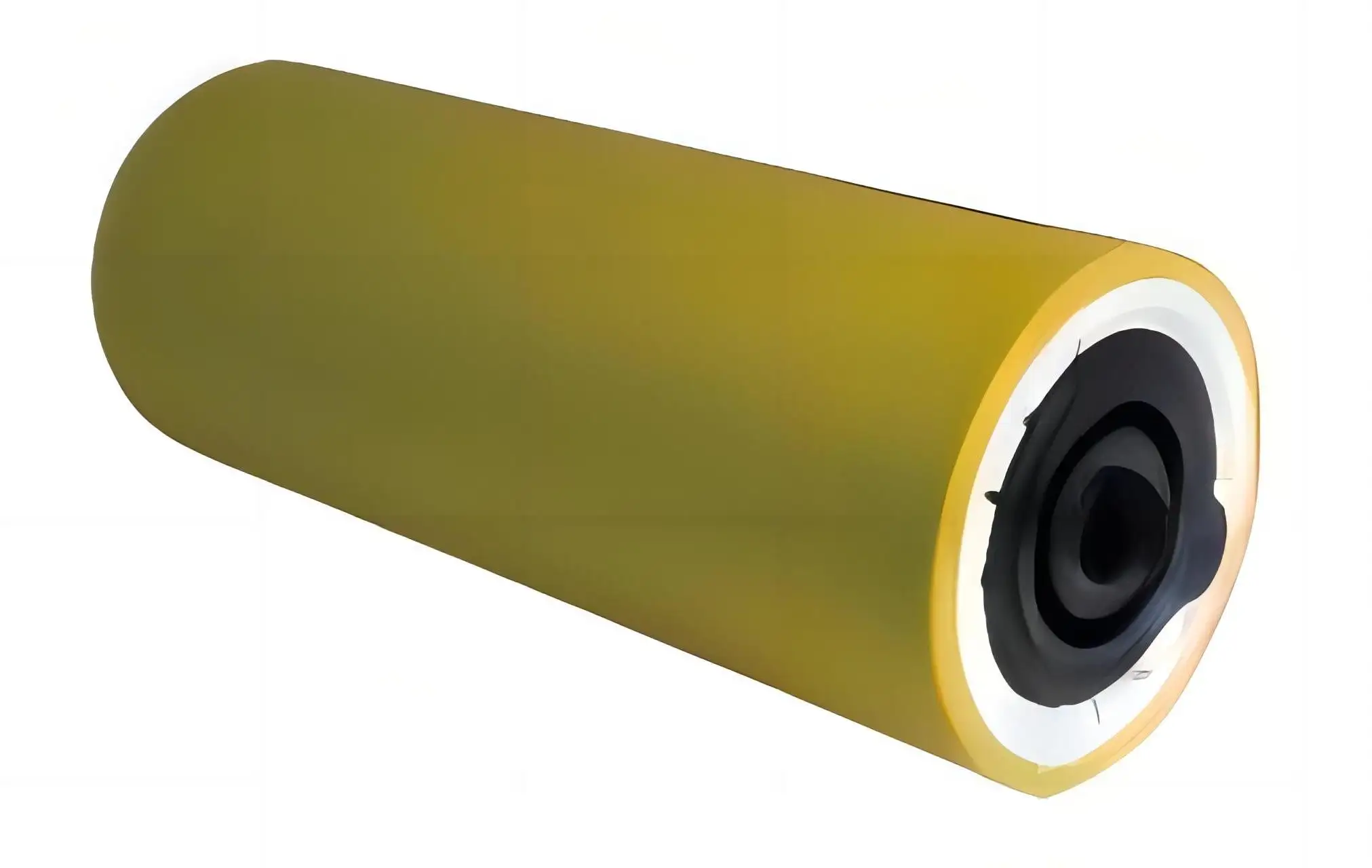

Conveyor Belt is the lifeblood of the bulk material transportation system, and its material selection is directly related to the stability and operational safety of the production line. From ordinary nylon (NN) Conveyor Belt, polyester (EP) Conveyor Belt to high-strength Steel Cord Conveyor Belt, there is a rigorous mechanical logic behind each material.

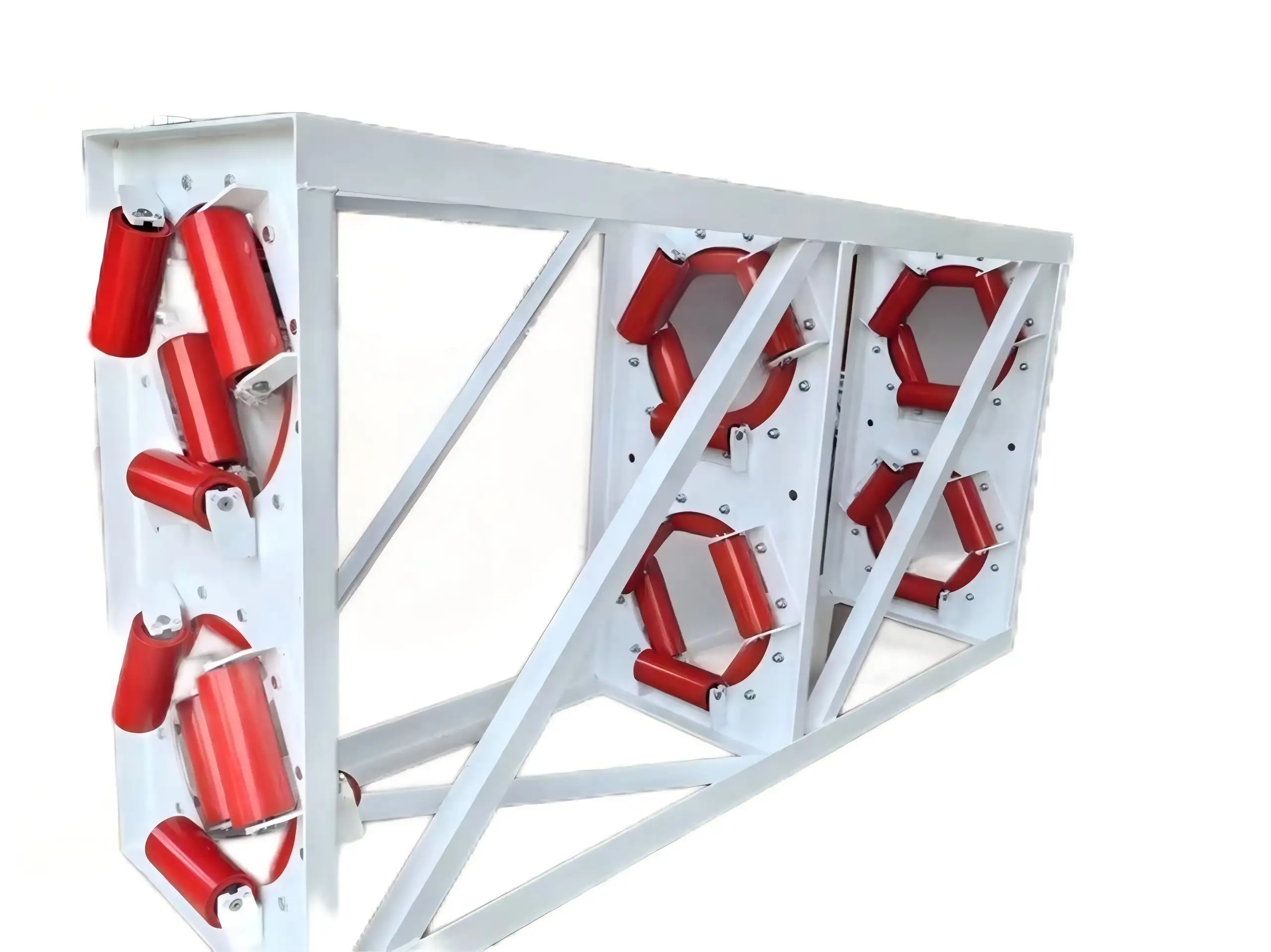

High-angle non-slip Chevron Conveyor Belt

The core of modern Conveyor Belt research and development is how to find the perfect balance between tensile strength, elongation and heat resistance. For long distance conveying, low elongation polyester canvas is the first choice ; For high-temperature working conditions such as cement and metallurgy, a specially formulated ethylene propylene diene rubber (EPDM) heat-resistant covering layer must be used.

Xinanneng reminds users that when selecting models, they should not only pay attention to the mechanical parameters of the belt body, but also pay attention to the performance indicators of the covering glue. For example, in humid and rainy open-pit mining areas, choosing an anti-slip Conveyor Belt with a "herringbone" or "U-shaped" pattern can effectively prevent materials from sliding down and increase the conveying inclination angle by more than 20%.

In the future, with the development of material science, lighter, stronger and more environmentally friendly composite material Conveyor Belt will become mainstream. Xinanneng will keep up with industry trends and provide customers with a full range of conveyor system support.