From carrying to protecting: In-depth analysis of the performance of HDPE, buffering and Idler With Rubber Disc under extreme working conditions

In modern bulk material conveying systems, although Idler is a basic component, its technical content directly affects the energy efficiency and safety of the entire production line. As the working environment becomes increasingly complex, a single steel Idler can no longer meet all needs. Targeted selection of load-bearing, buffering, comb-type or HDPE Idlers has become the key to improving the life of the system.

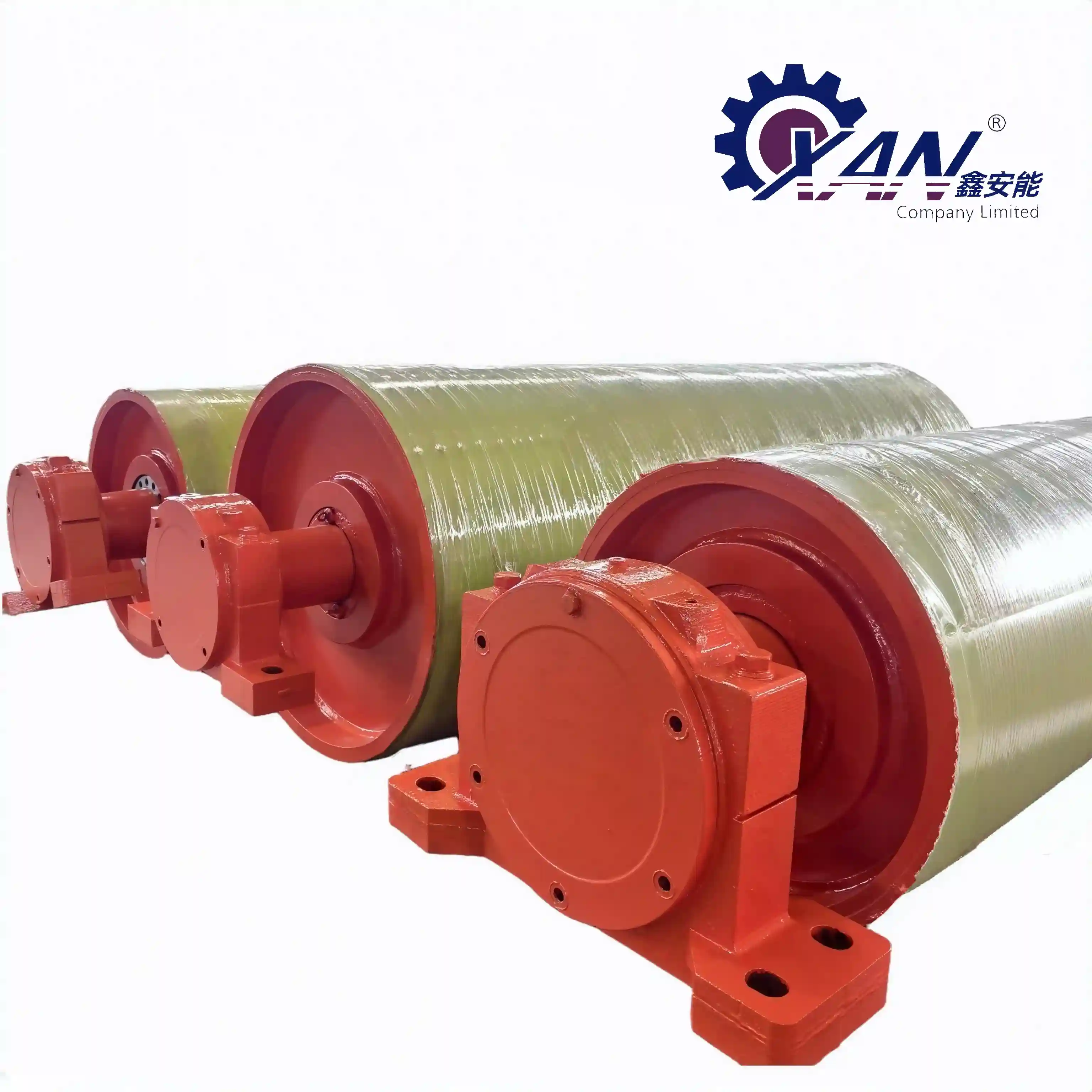

Xinanneng High Strength Precision Carrying Idler

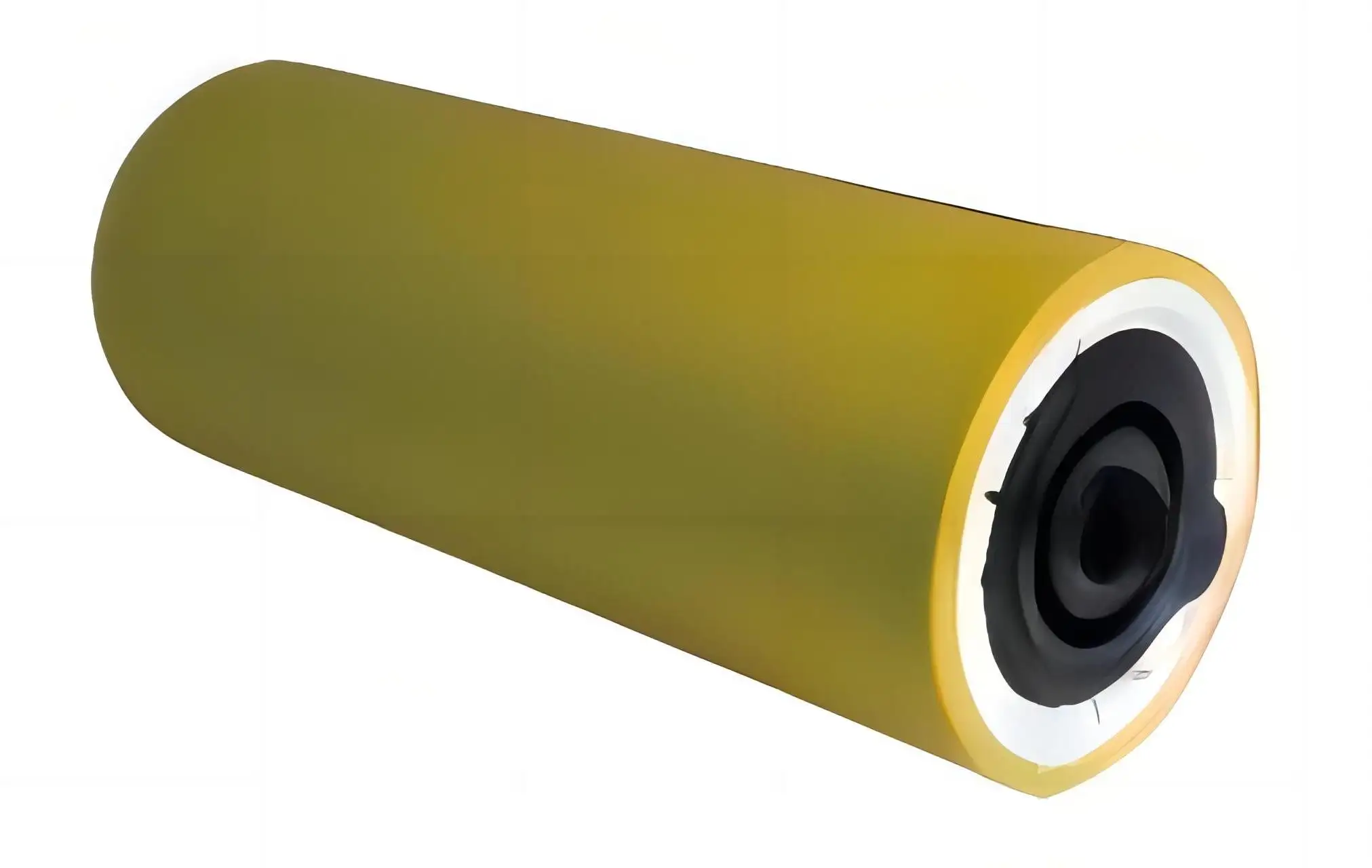

Impact idler with high elasticity at the receiving point

First, the precision carrying Idler is the cornerstone of smooth operation of the Conveyor Belt. Xinanneng adopts high-precision CNC pipe body processing technology to control the radial circular runout within 0.5mm. This extreme precision can significantly reduce the vibration of the Conveyor Belt during high-speed operation, which not only reduces the operating resistance (energy saving of more than 15%), but also effectively prevents material leakage caused by vibration. Its five-layer labyrinth seal structure ensures that the bearing can maintain tens of thousands of hours of maintenance-free operation in a dusty environment.

In the material receiving point area, the Conveyor Belt bears huge instantaneous impact force. At this time, Impact idler plays an irreplaceable role. By inserting a highly elastic and wear-resistant rubber ring on the outer surface of the roller, the Impact idler can effectively absorb the kinetic energy of the falling material and protect the Conveyor Belt from penetrating damage. Xinanneng's Impact idler uses specially formulated rubber, which not only has excellent recovery properties, but also maintains structural stability under high-frequency impact. It is the preferred protection solution for mining and dock loading and unloading.

Idler With Rubber Disc

Idler With Rubber Disc (rubber disc Idler) provides an ideal solution for the problem that sticky materials (such as wet coal, clay, etc.) tend to agglomerate on the Idler and cause the belt to deviate. The tiny vibrations generated by the rubber discs arranged at intervals during the rotation process can automatically peel off the adhesion on the surface of the belt and maintain the accuracy of the belt's running trajectory. This cleaning function reduces the frequency of manual maintenance and significantly improves the automated operation level of the system.

Lightweight corrosion-resistant HDPE polymer Idler

HDPE (high-density polyethylene) Idler, which represents the cutting-edge trend of the industry, is famous for its lightweight and corrosion resistance. Its weight is only 50% of the traditional steel Idler, which greatly reduces the starting load of the motor. More importantly, HDPE material is naturally resistant to acid and alkali corrosion, does not rust, and performs well in extremely harsh environments such as chemical industry and salt fields. In addition, the excellent sound-absorbing properties of polymer materials make the operating noise 10-15 decibels lower than that of steel Idlers. They are the core accessories for building a green and silent port.

To sum up, rationally matching different types of Idlers according to specific working conditions can not only significantly reduce system energy consumption, but also effectively prevent abnormal shutdown accidents. Xinanneng is committed to providing customers with a full range of Idler solutions from heavy-duty loading to special protection, helping companies achieve their business goals of reducing costs and increasing efficiency.